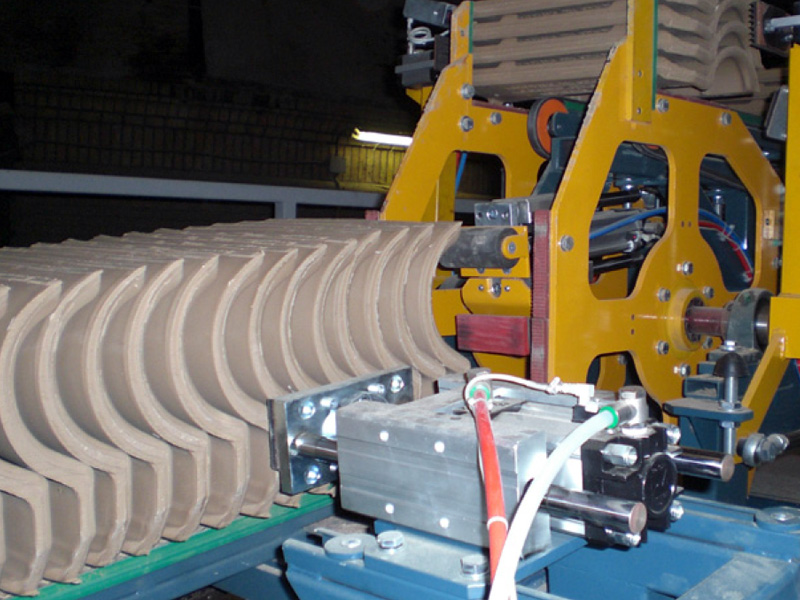

Loading solutions for heat treatment lines in any type of plant for bricks and extruded or structural ceramics

Kiln loading systems are at the center of the production of every plant for extruded or structural bricks and ceramic. This is why their ability to adapt to the characteristics and needs of each type of heat treatment line is fundamental. United Symbol can boast an experience gained in forty years in the brick and extruded ceramic sector, thanks to which it is now able to offer a complete range of solutions for loading systems for single-layer and superimposed layer tunnel kilns. , static chamber ovens, rapid ovens for cooking on plates and in the same way ovens of any other type.

Each loading system for heat treatment lines developed by United Symbol is custom-designed starting from the characteristics of each system and the specific needs of each customer. The careful implementation of the programming systems of the rows and layers first, and of the gripping organs then, allows precise manipulation of the dried and possibly treated product, guaranteeing its structural integrity. It is also possible to use both traditional gripping tools with pliers and the most modern models of anthropomorphic robots. Before delivery, the systems are tensioned by our specialized technical staff, while the highest quality is guaranteed at all times also by our assistance service, always available.

Product feature

- Design tailored to the needs of each customer

- Only the best machines and the best components

- Realization of loading systems for each type of oven

- Test equipment before delivery

- Complete assistance Italy – Abroad

Technical datasheet

Want more information about this product? Enter here your email and you will be sent the technical documentation and all the details to get in touch with our technicians